Unveiling the Secrets of Three-Proof Thermal Label Paper: Unlocking the Code to Diverse Application Scenarios with Superior Protection!

Release Time : 2026-01-05

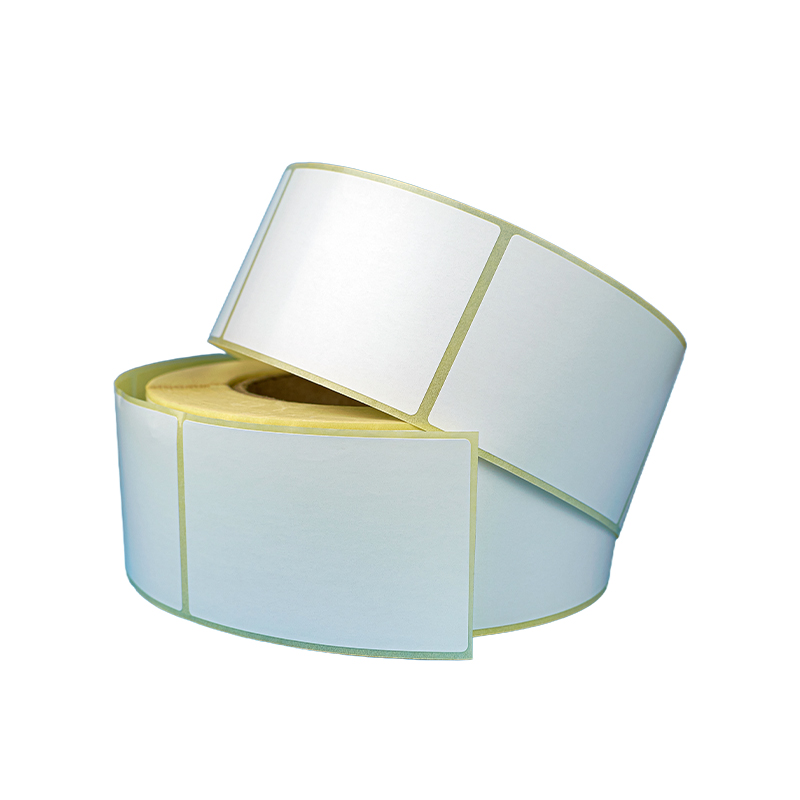

In fields highly reliant on label recognition, such as modern logistics, intelligent manufacturing, medical management, and retail distribution, traditional thermal paper, while offering advantages like convenient printing and low cost, has long been limited by its "fragile" characteristics—being susceptible to water, oil, and friction. Exposure to moisture, chemical reagents, or frequent contact can easily cause the text to blur or even disappear, leading to information loss, process interruptions, and even security risks. Three-proof thermal label paper—a high-performance thermal material possessing three core protective capabilities: waterproof, oil-proof, and scratch-resistant—is becoming the ideal choice for demanding application scenarios due to its superior environmental adaptability, quietly unlocking new possibilities for label applications in the Industry 4.0 era.

1. Triple Protection: Building a Durable and Reliable Physical Barrier for Information

The so-called "triple protection" is not simply a matter of layering coatings, but rather the construction of a dense protective film on top of the thermal layer through polymer composite coating technology. Its waterproof properties allow it to withstand rain, condensation, and even short-term immersion, making it suitable for high-humidity environments such as cold chain transportation and outdoor warehousing. Its oil-resistant properties effectively resist corrosion from common solvents such as engine oil, alcohol, and disinfectants, which is crucial in automotive manufacturing and medical equipment traceability. The surface hardening treatment significantly improves scratch and abrasion resistance, ensuring that printed content remains clear and legible even after repeated friction during forklift handling and express delivery sorting. This triple protection works synergistically to ensure that critical information is "always visible and always accurate" in complex processes.

2. Retaining the Advantages of Thermal Imaging, Balancing Efficiency and Environmental Protection

Unlike thermal transfer labels that require ribbons, the three-proof thermal paper still uses inkless printing technology, directly heating the printhead for color development. This eliminates the need for consumable replacements, significantly improving printing speed and equipment maintenance efficiency. Simultaneously, the ribbonless design reduces plastic waste, aligning with green manufacturing trends. More importantly, its thermal coating has been optimized to maintain high sensitivity while improving image stability—it is less prone to yellowing or fading even after prolonged exposure to light or high temperatures, meeting archival preservation requirements.

3. Versatile Applications: A Versatile Choice from Factory Workshops to Hospital Pharmacies

The application boundaries of three-proof thermal label paper are constantly expanding. In the field of smart manufacturing, it is used to label semi-finished products such as PCB boards and engine parts that require cleaning and spraying processes, withstanding the chemical environment of the production line; in cold chain logistics, it is attached to the outer packaging of frozen food, remaining flexible and non-brittle even at -30℃, with clear lettering; in the medical industry, it is used for tracking labels of medicines, samples, and instruments, withstanding alcohol wiping and pre-treatment before autoclaving; during peak express delivery periods, even if packages are rained on or stacked and squeezed, the label information remains intact, ensuring sorting accuracy. It is widely compatible with mainstream thermal printers, allowing for upgrades without equipment modifications.

4. Safety, Compliance, and Sustainability in Balance

High-quality three-proof thermal paper strictly adheres to environmental regulations, making it particularly suitable for food contact or children's product labels. Some manufacturers have even launched versions with biodegradable substrates, reducing environmental burden while maintaining performance. Furthermore, its high reliability reduces the costs of rework, recalls, or data reconstruction due to label failure, achieving a win-win situation for both economic benefits and risk management from a full lifecycle perspective.

The rise of three-proof thermal label paper marks a leap in label materials from simply "usable" to "reliable, durable, and intelligent." It is not only an information carrier but also a robust link connecting the physical world and digital systems. In an era of interconnectedness and end-to-end traceability, this seemingly ordinary paper, with its silent yet resilient presence, safeguards the accuracy and security of every product, every piece of data, and every transaction—truly unlocking limitless application possibilities across diverse scenarios with its superior protection.

1. Triple Protection: Building a Durable and Reliable Physical Barrier for Information

The so-called "triple protection" is not simply a matter of layering coatings, but rather the construction of a dense protective film on top of the thermal layer through polymer composite coating technology. Its waterproof properties allow it to withstand rain, condensation, and even short-term immersion, making it suitable for high-humidity environments such as cold chain transportation and outdoor warehousing. Its oil-resistant properties effectively resist corrosion from common solvents such as engine oil, alcohol, and disinfectants, which is crucial in automotive manufacturing and medical equipment traceability. The surface hardening treatment significantly improves scratch and abrasion resistance, ensuring that printed content remains clear and legible even after repeated friction during forklift handling and express delivery sorting. This triple protection works synergistically to ensure that critical information is "always visible and always accurate" in complex processes.

2. Retaining the Advantages of Thermal Imaging, Balancing Efficiency and Environmental Protection

Unlike thermal transfer labels that require ribbons, the three-proof thermal paper still uses inkless printing technology, directly heating the printhead for color development. This eliminates the need for consumable replacements, significantly improving printing speed and equipment maintenance efficiency. Simultaneously, the ribbonless design reduces plastic waste, aligning with green manufacturing trends. More importantly, its thermal coating has been optimized to maintain high sensitivity while improving image stability—it is less prone to yellowing or fading even after prolonged exposure to light or high temperatures, meeting archival preservation requirements.

3. Versatile Applications: A Versatile Choice from Factory Workshops to Hospital Pharmacies

The application boundaries of three-proof thermal label paper are constantly expanding. In the field of smart manufacturing, it is used to label semi-finished products such as PCB boards and engine parts that require cleaning and spraying processes, withstanding the chemical environment of the production line; in cold chain logistics, it is attached to the outer packaging of frozen food, remaining flexible and non-brittle even at -30℃, with clear lettering; in the medical industry, it is used for tracking labels of medicines, samples, and instruments, withstanding alcohol wiping and pre-treatment before autoclaving; during peak express delivery periods, even if packages are rained on or stacked and squeezed, the label information remains intact, ensuring sorting accuracy. It is widely compatible with mainstream thermal printers, allowing for upgrades without equipment modifications.

4. Safety, Compliance, and Sustainability in Balance

High-quality three-proof thermal paper strictly adheres to environmental regulations, making it particularly suitable for food contact or children's product labels. Some manufacturers have even launched versions with biodegradable substrates, reducing environmental burden while maintaining performance. Furthermore, its high reliability reduces the costs of rework, recalls, or data reconstruction due to label failure, achieving a win-win situation for both economic benefits and risk management from a full lifecycle perspective.

The rise of three-proof thermal label paper marks a leap in label materials from simply "usable" to "reliable, durable, and intelligent." It is not only an information carrier but also a robust link connecting the physical world and digital systems. In an era of interconnectedness and end-to-end traceability, this seemingly ordinary paper, with its silent yet resilient presence, safeguards the accuracy and security of every product, every piece of data, and every transaction—truly unlocking limitless application possibilities across diverse scenarios with its superior protection.