Are the grid lines on the back of grid thermal tag paper precisely aligned to ensure consistent tear length and reduce waste?

Release Time : 2025-12-10

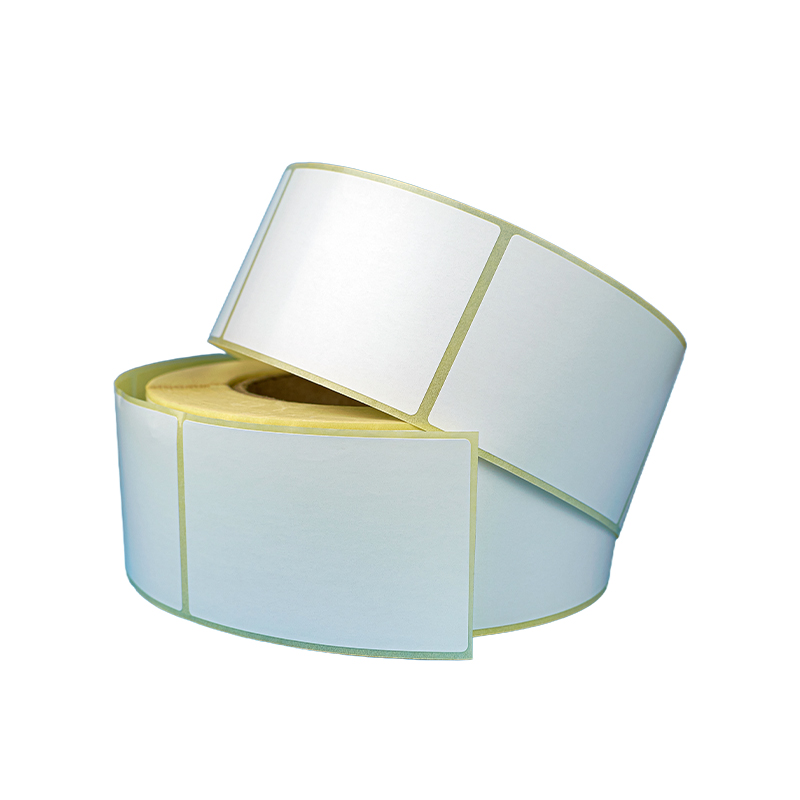

In the daily operations of modern logistics, warehousing management, and retail, labels, though small, are crucial carriers of information. Especially in high-frequency, fast-paced environments, grid thermal tag paper, with its unique grid line design on the back, has become an important tool for improving efficiency and controlling costs. The precise alignment of the grid lines directly determines the accuracy of each tear and the economy of material usage—this seemingly minor technological detail actually concerns the smoothness and sustainability of the entire supply chain.

Grid thermal tag paper is typically supplied in rolls, with regularly arranged dotted or dotted cutting lines printed on the back, forming a "grid" structure. Its core purpose is to allow users to easily tear off the desired length of label along the preset lines using only their fingers, without the need for scissors or cutting equipment. However, if the grid lines are misaligned, misaligned, or unevenly spaced during manufacturing, the tear-off length will vary greatly: too long results in material waste, while too short prevents complete printing and may even require relabeling, increasing material costs and slowing down operations.

Precisely aligned grid lines stem from high-precision die-cutting and printing process control. During production, the base paper and thermal coating undergo multiple processes simultaneously. Any tension fluctuations, registration errors, or die wear can affect the final grid consistency. High-quality products use a closed-loop control system to monitor the paper feed position and cutting depth in real time, ensuring that each grid line is strictly equidistant, straight, and of appropriate depth—easily tearable without being too deep and causing the label to accidentally separate during printing or transportation.

The value of this consistency far exceeds simply saving a sheet of paper. In express sorting centers, operators handle hundreds of packages per hour. If each label tear requires visual inspection or adjustment, the accumulated time loss would be considerable. On automated labeling lines, inconsistent label lengths can lead to feeding jams, positioning misalignments, and even machine downtime. Precise grid lines facilitate smoother manual operations and more reliable machine recognition, enabling highly efficient human-machine collaboration.

Furthermore, reducing waste is not only a cost issue but also a reflection of environmental responsibility. Although label paper is made from recycled paper, its production still consumes water, energy, and chemical materials. Every unnecessary cut or scrap represents a hidden consumption of resources. Precise grid design maximizes material utilization through "on-demand use," aligning with the development trends of green logistics and sustainable packaging.

It is worth mentioning that high-quality grid lines are not only precisely positioned but also meticulously calibrated for tear resistance. The tear should be crisp and clean, without burrs or frayed edges, preventing residual fibers from affecting subsequent printhead cleaning or even application smoothness. Simultaneously, the grid depth must be just right—too shallow and it's difficult to tear, too deep and it weakens the overall strength of the roll, making it prone to breakage during high-speed printing.

From a user experience perspective, the precisely aligned grid lines convey a sense of respect and attention to detail: they make operations easier for frontline staff, give managers greater control over consumable usage, and make the entire system run more quietly and with fewer errors.

In short, the precise alignment of the grid lines on the back of the grid thermal tag paper is not merely a simple technological specification, but a concentrated manifestation of efficiency, economy, and reliability at the microscopic level. It makes each tear a silent optimization, quietly safeguarding the order and rhythm of the logistics world in the daily routine—within a small space, craftsmanship, efficiency, and responsibility are evident.

Grid thermal tag paper is typically supplied in rolls, with regularly arranged dotted or dotted cutting lines printed on the back, forming a "grid" structure. Its core purpose is to allow users to easily tear off the desired length of label along the preset lines using only their fingers, without the need for scissors or cutting equipment. However, if the grid lines are misaligned, misaligned, or unevenly spaced during manufacturing, the tear-off length will vary greatly: too long results in material waste, while too short prevents complete printing and may even require relabeling, increasing material costs and slowing down operations.

Precisely aligned grid lines stem from high-precision die-cutting and printing process control. During production, the base paper and thermal coating undergo multiple processes simultaneously. Any tension fluctuations, registration errors, or die wear can affect the final grid consistency. High-quality products use a closed-loop control system to monitor the paper feed position and cutting depth in real time, ensuring that each grid line is strictly equidistant, straight, and of appropriate depth—easily tearable without being too deep and causing the label to accidentally separate during printing or transportation.

The value of this consistency far exceeds simply saving a sheet of paper. In express sorting centers, operators handle hundreds of packages per hour. If each label tear requires visual inspection or adjustment, the accumulated time loss would be considerable. On automated labeling lines, inconsistent label lengths can lead to feeding jams, positioning misalignments, and even machine downtime. Precise grid lines facilitate smoother manual operations and more reliable machine recognition, enabling highly efficient human-machine collaboration.

Furthermore, reducing waste is not only a cost issue but also a reflection of environmental responsibility. Although label paper is made from recycled paper, its production still consumes water, energy, and chemical materials. Every unnecessary cut or scrap represents a hidden consumption of resources. Precise grid design maximizes material utilization through "on-demand use," aligning with the development trends of green logistics and sustainable packaging.

It is worth mentioning that high-quality grid lines are not only precisely positioned but also meticulously calibrated for tear resistance. The tear should be crisp and clean, without burrs or frayed edges, preventing residual fibers from affecting subsequent printhead cleaning or even application smoothness. Simultaneously, the grid depth must be just right—too shallow and it's difficult to tear, too deep and it weakens the overall strength of the roll, making it prone to breakage during high-speed printing.

From a user experience perspective, the precisely aligned grid lines convey a sense of respect and attention to detail: they make operations easier for frontline staff, give managers greater control over consumable usage, and make the entire system run more quietly and with fewer errors.

In short, the precise alignment of the grid lines on the back of the grid thermal tag paper is not merely a simple technological specification, but a concentrated manifestation of efficiency, economy, and reliability at the microscopic level. It makes each tear a silent optimization, quietly safeguarding the order and rhythm of the logistics world in the daily routine—within a small space, craftsmanship, efficiency, and responsibility are evident.